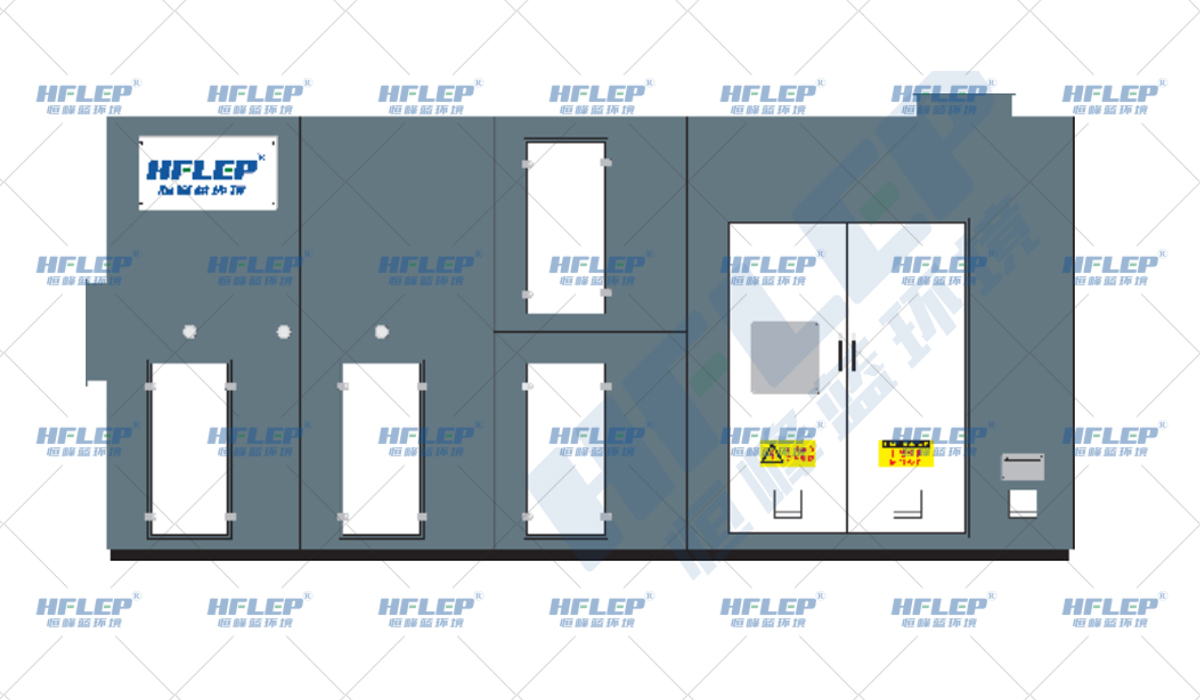

Packaging Printing

○ Packaging printing is a variety of packaging materials for the carrier of the printing, printing on the packaging of decorative patterns, patterns or text, as a way to make the product more attractive or more descriptive, so as to play a role in conveying information and increase sales. Including packaging cartons, bottles, cans and other printing. The production of a large number of coloured inks and organic thinner, these solvents in the production of products as well as the drying process of organic compounds emitted, alcohol wetting solution in the isopropyl alcohol, wireless gluing and binding....

Detail

>

>

Guangdong Public Security Bureau No. 44190002006305

Guangdong Public Security Bureau No. 44190002006305